Shipping containers are renowned for their unmatched strength and durability, making them the preferred choice for various applications beyond their original purpose of transporting goods. From off-grid living to innovative architectural designs, these robust structures have captivated the imagination of many. But what exactly enables shipping containers to withstand the harsh conditions of transporting heavy cargo across vast distances, endure extreme weather conditions, and serve as the foundation for unconventional living spaces? In this article, I will explore the engineering marvel behind the strength of shipping containers, shedding light on the materials and design principles that contribute to their remarkable structural integrity.

Design and Construction of Shipping Containers

Overview

Shipping containers are a crucial component of international trade and transportation. These large metal structures are designed to store and transport goods efficiently, securely, and safely across various transportation modes. Their robust construction allows them to withstand harsh environmental conditions and protect the cargo they carry. In this article, I will explore the design and construction aspects of shipping containers, focusing on their material composition, load-bearing capabilities, corrosion resistance, protection against external forces, standardization and testing, reinforcements and modifications, longevity and durability, transportation efficiency, fire resistance, and security features.

Material Used

Shipping containers are primarily constructed using two materials: corten steel and aluminum alloy. Corten steel, also known as weathering steel, is a high-strength steel alloy that exhibits exceptional corrosion resistance. This makes it suitable for enduring the rigors of ocean transportation and exposure to harsh environments. Aluminum alloy containers, on the other hand, offer a lightweight alternative to steel, making them more viable for air and rail transportation. These materials, combined with the container’s structural design, contribute to its overall strength and durability.

Structural Design

Shipping containers are ingeniously designed to withstand the dynamic forces experienced during transportation by land, sea, and air. The structure consists of a rectangular prism-shaped body with corrugated walls, reinforced corners, and a standardized interchangeable corner casting system. These interlocking corner castings allow for efficient stacking and secure connection of containers. The roof is typically constructed with corrugated steel panels, while the floor consists of marine-grade plywood or steel to withstand heavy loads. Reinforcing bands and bracings distribute the forces evenly, enhancing the container’s load-bearing capabilities.

Interlocking Corner Castings

Interlocking corner castings play a vital role in the overall structural integrity of shipping containers. Located at the top and bottom corners of each container, these castings are precisely positioned and uniformly spaced to ensure compatibility and stability during stacking and intermodal transportation. The standardized design allows containers to be securely fastened together using twist locks or lashing systems. This ensures that cargo remains secure even when exposed to various environmental and transportation conditions.

Load-Bearing Capabilities

The load-bearing capabilities of shipping containers are of utmost importance to ensure the safe transportation of goods. Containers are designed to withstand both static and dynamic loads. Here, we will explore three aspects of load-bearing capabilities: stacking ability, distributed load, and structural integrity.

Stacking Ability

One of the key features of shipping containers is their ability to be stacked vertically. This allows efficient space utilization during storage and transportation. The interlocking corner castings, reinforced structure, and standardized dimensions enable containers to be safely stacked, often reaching heights of several stories. However, there are limitations to the stacking ability to prevent structural damage and ensure stability. Container manufacturers and transportation organizations provide guidelines and regulations for safe stacking practices.

Distributed Load

Shipping containers are designed to handle distributed loads, which are evenly distributed across their floors. This is essential to prevent localized stress concentrations that could result in structural failure. The floors of containers are engineered to withstand heavy loads, often up to 30,000 kilograms or more. Marine-grade plywood or steel flooring offers the necessary strength and durability to distribute the load effectively.

Structural Integrity

To ensure the structural integrity of shipping containers, various design features and reinforcements are incorporated into their construction. Reinforcing bands and bracings provide additional strength and prevent the container from deforming under heavy loads. These structural elements distribute the forces evenly, minimizing stress concentrations and enhancing the container’s overall strength.

Corrosion Resistance

Shipping containers are exposed to a variety of environmental conditions, including salty ocean air, rain, and extreme temperatures, which can contribute to corrosion and degradation. To enhance their durability, containers are equipped with corrosion-resistant coatings and made from materials that exhibit excellent resistance to corrosion. Let’s explore the various aspects of corrosion resistance in shipping containers.

Corrosion-Resistant Coatings

To protect against corrosion, shipping containers are coated with specialized paints or protective coatings. These coatings act as a barrier, preventing moisture penetration and inhibiting the formation of rust. They are designed to withstand the harsh conditions encountered during transportation and storage, extending the container’s lifespan.

Aluminum Alloy Containers

Aluminum alloy containers offer inherent corrosion resistance due to the natural oxide layer that forms on their surface. This oxide layer acts as a protective barrier, preventing further oxidation and corrosion. Aluminum containers are often preferred for applications where weight reduction and corrosion resistance are critical, such as air freight and intermodal transportation.

Corten Steel

Corten steel, commonly used in the construction of shipping containers, possesses excellent corrosion resistance properties. It forms a protective patina layer on its surface, which acts as a shield against further corrosion. Corten steel containers demonstrate exceptional durability and are widely utilized in marine environments characterized by high humidity and saltwater exposure.

Maintenance and Inspections

Regular maintenance and inspections are crucial to ensure the ongoing corrosion resistance of shipping containers. Containers should be inspected for any signs of corrosion, such as rusted areas or paint deterioration. These issues should be addressed promptly to prevent further damage. Corrosion-affected areas can be treated, and necessary repairs carried out to maintain the container’s integrity.

Protection Against External Forces

Shipping containers are subject to a variety of external forces and hazards during transportation and storage. Robust design and construction features enable containers to withstand impacts, severe weather conditions, vibrations, shocks, and crane handling. Let’s delve into each aspect of protection against external forces.

Impact Resistance

Shipping containers are built with reinforced corners and rigid structures to withstand impact forces. This ensures that the cargo inside remains undamaged even in the event of minor collisions or accidents. The materials used, such as corten steel or aluminum alloy, contribute to the container’s overall impact resistance. However, in extreme cases, severe impacts can cause damage, leading to compromised structural integrity.

Severe Weather Conditions

Shipping containers are designed to withstand a wide range of weather conditions, including extreme temperatures, heavy rain, strong winds, and even hurricanes. The robust construction and corrosion-resistant materials provide protection against external elements. Proper sealing and weatherproofing techniques are employed to minimize water ingress and prevent damage to the container and its contents.

Vibrations and Shocks

During transportation, shipping containers are exposed to vibrations and shocks caused by uneven road surfaces, rough seas, or heavy machinery. The structural design, reinforced corners, and bracing systems help mitigate these vibrations and shocks, minimizing the impact on the cargo inside. Furthermore, containers are filled with cushioning materials, such as airbags, to absorb shocks and protect fragile items.

Crane Handling

Shipping containers are frequently lifted and maneuvered using cranes during loading and unloading operations. The design and construction of containers consider these handling procedures, ensuring that containers can withstand the stresses imparted by cranes. Reinforced corners, engineered lifting points, and structural stability facilitate safe and efficient crane handling.

Standardization and Testing

Standardization and testing play a crucial role in ensuring the quality, safety, and compatibility of shipping containers. International standards, strength testing, quality control processes, and certifications are utilized to maintain industry-wide consistency. Let’s explore these aspects in detail.

ISO Standards

The International Organization for Standardization (ISO) establishes and maintains standards for shipping containers to ensure uniformity and compatibility. ISO container standards define dimensions, corner fittings, and testing procedures. These standards enable containers from different manufacturers to interlock securely, ensuring safe stacking and transportation.

Strength Testing

Shipping containers undergo rigorous testing to validate their load-bearing capabilities, structural integrity, and resistance to external forces. Strength tests include static and dynamic load tests, corner post tests, roof strength tests, floor strength tests, and tests to assess stacking ability. These tests ensure that containers meet specific strength requirements and can withstand the forces encountered during transportation.

Quality Control

Quality control processes are implemented throughout the manufacturing and maintenance of shipping containers. These processes involve strict adherence to manufacturing standards, inspections, and quality assurance tests. Containers are inspected for dimensional accuracy, proper welding techniques, corrosion resistance, structural integrity, and overall quality.

Certifications

Shipping containers may obtain certifications from various regulatory bodies or industry organizations to validate their compliance with standards and regulations. Certifications like CSC (Container Safety Convention) approval ensure that containers are safe for international shipping. Other certifications, such as ISO 9001, signify compliance with quality management standards.

Reinforcements and Modifications

Shipping containers can be reinforced and modified to meet specific requirements or accommodate specialized cargo. Reinforcements and modifications enhance the container’s strength, security, and versatility. Here are some common reinforcement and modification options.

Corner Castings

Corner castings, the interlocking components of shipping containers, can be reinforced or made more durable to withstand additional stress or heavy loads. Strengthened corner castings ensure the overall structural integrity of the container remains intact, even when subjected to extreme forces.

Additional Reinforcements

For applications that involve the transport of heavy or delicate cargo, additional reinforcements can be added to specific areas of the container. These reinforcements, such as steel bracings or frame reinforcements, provide increased strength and structural support, minimizing the risk of damage to the cargo.

Cutouts and Openings

Containers can be customized with cutouts and openings to facilitate the loading, unloading, or storage of specific cargo. Careful engineering and reinforcement are necessary when making such modifications to ensure the structural integrity of the container is not compromised. Common examples include roll-up doors, side access doors, or ventilation systems.

Customization Options

Container customization allows for the adaptation of containers to unique requirements. Modifications can include interior insulation, electrical installations, climate control systems, or partitioning for compartmentalized storage. These customizations optimize the container’s functionality, making it suitable for specialized applications, such as refrigerated storage or mobile offices.

Longevity and Durability

Shipping containers are designed to have a long lifespan while enduring the harsh conditions encountered during transportation and storage. Factors such as materials used, corrosion resistance, structural design, and maintenance practices contribute to their durability and longevity.

Life Span

With proper maintenance and regular inspections, shipping containers can have a lifespan of 15 to 20 years or more. Regular maintenance, including repainting, addressing corrosion, and replacing damaged components, ensures the container remains in optimal condition and extends its functional life.

Toughness in Different Environments

Shipping containers are built to withstand various environments, making them suitable for international shipping. Whether it is the corrosive saltwater environments of marine transportation or the extreme temperatures of desert regions, containers are designed to withstand these conditions. The use of suitable materials and corrosion-resistant coatings contribute to their toughness and durability.

Resistant to Wear and Tear

The materials used in shipping containers, such as corten steel or aluminum alloys, offer high resistance to wear and tear. Containers are built to withstand repeated loading and unloading procedures, stacking, transportation, and exposure to external elements without compromising their structural integrity. Proper maintenance and regular inspections help identify and address any signs of wear and tear promptly.

Reuse and Recycling

Shipping containers have the potential for extensive reuse and recycling. Even after their primary use for transportation, containers can be repurposed as storage units, modular buildings, or off-grid housing. Their robust construction and durability make them suitable for such applications, reducing waste and promoting sustainable practices within the construction industry.

Transportation Efficiency

Shipping containers play a pivotal role in the efficiency of transportation systems, offering advantages in intermodal transportation, space utilization, and ease of handling during loading and unloading operations.

Intermodal Transportation

The standardized dimensions and compatibility of shipping containers enable seamless intermodal transportation. Containers can be efficiently transferred from ships to trucks, trains, or barges without the need for manual handling or cargo transfer. This significantly reduces the time and effort required for cargo transfer, streamlining the transportation process.

Optimized Space Utilization

Shipping containers are designed to maximize space utilization, both during transportation and storage. Their standardized dimensions allow for efficient packing and stacking, minimizing empty spaces. This optimization translates into increased cargo capacity per transport unit, reducing transportation costs and carbon emissions.

Handling and Stacking

Containers are designed with built-in features that facilitate efficient handling and stacking. The interlocking corner castings, reinforced corners, and standardized dimensions allow for safe and secure handling using cranes, forklifts, or other lifting equipment. The ability to stack containers vertically saves valuable land space during storage and transportation.

Ease of Loading and Unloading

Shipping containers offer easy access for loading and unloading procedures. The large doors at one end facilitate the movement of cargo, enabling fast and efficient loading or unloading operations. This reduces turnaround time at ports, warehouses, and distribution centers, increasing overall operational efficiency.

Fire Resistance

The fire resistance of shipping containers is a critical aspect, especially when transporting goods that may be highly flammable. Design features and protective measures are implemented to minimize the risk of fire propagation and ensure the safety of both the cargo and personnel involved.

Non-Combustible Materials

Shipping containers are primarily constructed using non-combustible materials such as corten steel or aluminum alloys. These materials have high melting points and do not contribute to the spread of fire, providing inherent fire resistance. The use of non-combustible materials mitigates the risk of fire-related accidents during transportation.

Fire Suppression Systems

To enhance fire safety, shipping containers can be equipped with fire suppression systems. These systems can include fire extinguishers, sprinkler systems, or specialized foam installations. These measures help prevent or suppress fires, reducing the potential damage to cargo and minimizing the risk to personnel.

Safety Measures

Shipping containers adhere to safety regulations to prevent fire-related incidents during transportation. Strict guidelines may include requirements for hazardous material containers, proper labeling and documentation, and compliance with fire safety standards set by national and international bodies. These safety measures ensure that containers meet the necessary requirements to minimize the risk of fire accidents.

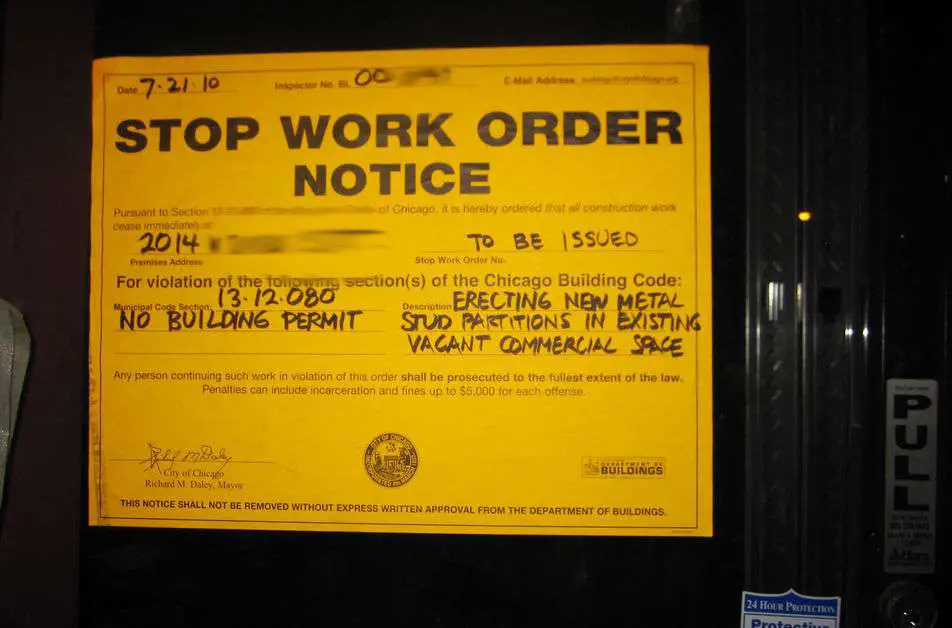

Regulations and Code Compliance

Shipping containers must comply with various regulations and codes regarding fire safety. These regulations often include guidelines on container design, materials used, fire retardant properties, and testing procedures. Compliance ensures that shipping containers meet the necessary standards and can safely transport goods, particularly those prone to fire hazards.

Security Features

Shipping containers offer security features to protect the cargo from theft, tampering, and unauthorized access. These features ensure the integrity and confidentiality of the transported goods, providing peace of mind for shippers and consignees.

Locking Mechanisms

Shipping containers are equipped with robust locking mechanisms designed to prevent unauthorized access. Common locking mechanisms include padlocks, lockboxes, and twist locks. These mechanisms require specific tools or keys to open, enhancing security and deterring theft or tampering.

Tamper-Proof Designs

Containers are built with tamper-proof designs to provide an additional layer of security. Tamper-proof seals and bolts are utilized to prevent unauthorized entry and indicate any attempts at tampering. These designs help maintain the integrity of the cargo and enable the identification of potential security breaches.

Seal Integrity

Shipping containers utilize seals to secure their doors and prevent unauthorized opening. These seals are often made of high-strength materials and feature unique serial numbers or barcodes. Any tampering or attempted breach will be indicated by a broken seal, alerting the shipping company or recipient to a potential security issue.

Surveillance and Tracking Systems

Advanced shipping containers may incorporate surveillance and tracking systems to monitor their location and security status. These systems can include GPS tracking, CCTV cameras, or intrusion detection sensors. Such technologies enhance security measures, ensuring the real-time monitoring of containers and immediate response to any security breaches.

In conclusion, shipping containers are remarkable engineering achievements that revolutionized global trade and transportation. Their design and construction, combined with high-strength materials, structural integrity, corrosion resistance, and various security features, enable safe and efficient shipment of goods across different modes of transportation. The standardization, testing, and customization options further enhance their versatility and adaptability to diverse cargo requirements. By continuously improving their strength, durability, and environmental performance, shipping containers continue to play a vital role in facilitating international commerce while promoting sustainability and safety.